Roland METAZA MPX-95

Your shopping cart is empty!

Product Description

Roland Metaza MPX-95

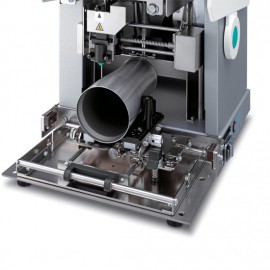

Perfect for gift personalization or medical and industrial part marking, the new METAZA MPX-95 photo impact printer is a cost-effective, easy-to-operate device that anyone can use to mark gold, steel, silver and titanium.

Added Versatility with Removable Base and Optional Kits

The MPX-95 introduces new features for imprinting onto more gift items and a wider range of equipment. These include a removable base plate and base unit to allow imprinting onto larger items, and the following kits for expanding application possibilities:

Gift Kit

Featuring a standard center vise and adjustable clamp-pin vise, the Gift Kit supports personalization of simple metal items plus curved and irregularly shaped items. The Gift Kit is an essential addition for gift personalization.

DPM Kit

Featuring a DPM vise and adjustable clamp-pin vise, the DPM Kit allows users to effectively mark onto simple and intricately shaped surgical instruments, industrial parts and tools. The DPM Kit is an essential addition for marking tools and surgical items.

More Precision, Less Fuss

Without debris, noise or odor, users can add photo quality detail and complex barcode data to a printable area as small as one square millimeter and as large as 80 millimeters. There’s far better accuracy and a lot less clean-up with an MPX-95.

Other Distinguishing Features

- Diamond-tipped stylus marks silver, copper, platinum, brass, and aluminum up to 200HV

- Includes easy-to-use METAZA Studio software � DPM version features 2D symbol code creator

- Built-in laser pointer for quick and precise imprint set-up

- Automatic surface detection

- Variable data printing capabilities for applying sequential data

- Compact and fully enclosed

Roland MPX-95 Specifications

| Model | MPX-95 | |

|---|---|---|

| Imprintable material | Gold, silver, copper, platinum, brass, aluminum, iron, stainless steel, titanium, etc. (Vickers hardness [HV] of the imprint surface must be 200 or less.) | |

| Loadable material size | Using a base table + base plate: | Max. 3.9 in (W). X 7.9 in. (L) X 1.6 in. (H) (100 mm (W) X 200 mm (L) X 40 mm (H)) or 7.9 in. (W) X 3.9 in. (L) X 1.6 in. (H) (200 mm (W) X 100 mm (L) X 40 mm (H)) |

| Using a base plate only: | Max. 3.9 in. (W) X 7.9 in. (L) X 2.8 in. (H) (100 mm (W) X 200 mm (L) X 70 mm (H)) or 7.9 in. X 3.9 in. X 2.8 in. (200 mm (W) X 100 mm (L) X 70 mm (H)) *The above are for when the cover is closed. When the cover is open, there is no limit on how large the material can be, but the imprint area of the material must be placed within the imprint area. | |

| Imprint area | Maximum imprintable area | 3.2 in. (W) X 3.2 in. (D) X 2.8 in. (H) 80 mm (W) X 80 mm (D) X 70 mm (H) |

| Recommended imprint area | 2.0 in. (W) X 2.0 in. (D) X 2.8 in (H) 50 mm (W) . 50 mm (D) . 70 mm (H) | |

| Resolution | High resolution | 529 dpi |

| Photo | 353 dpi | |

| Text | 265 dpi | |

| Vector | 1058 dpi | |

| Imprint direction | Unidirectional imprinting or bidirectional imprinting (Selectable with Windows driver) | |

| Imprint speed (Default) | Photo | 2.0 in./sec (50 mm/sec) |

| High resolution/Text | 1.2 in./sec (33 mm/sec) | |

| Vector | 0.94 in./sec (24 mm/sec) | |

| Interface | USB | |

| Power requirements | Dedicated AC adapter | AC 100 to 240 V �10%, 50/60 Hz |

| Main unit | DC 19 V, 1.2 A | |

| Power consumption | Approx. 21 W | |

| Operating noise | 70 dB (A) or less | |

| Operating temperature | 50 to 86�F (10 to 30�C) | |

| Operating humidity | 35 to 80% (no condensation) | |

| External dimensions | 11.3 in. (W) x 15.1 in. (D) x 12.2 in. (H) 286 mm (W) x 383 mm (D) x 308 mm (H) | |